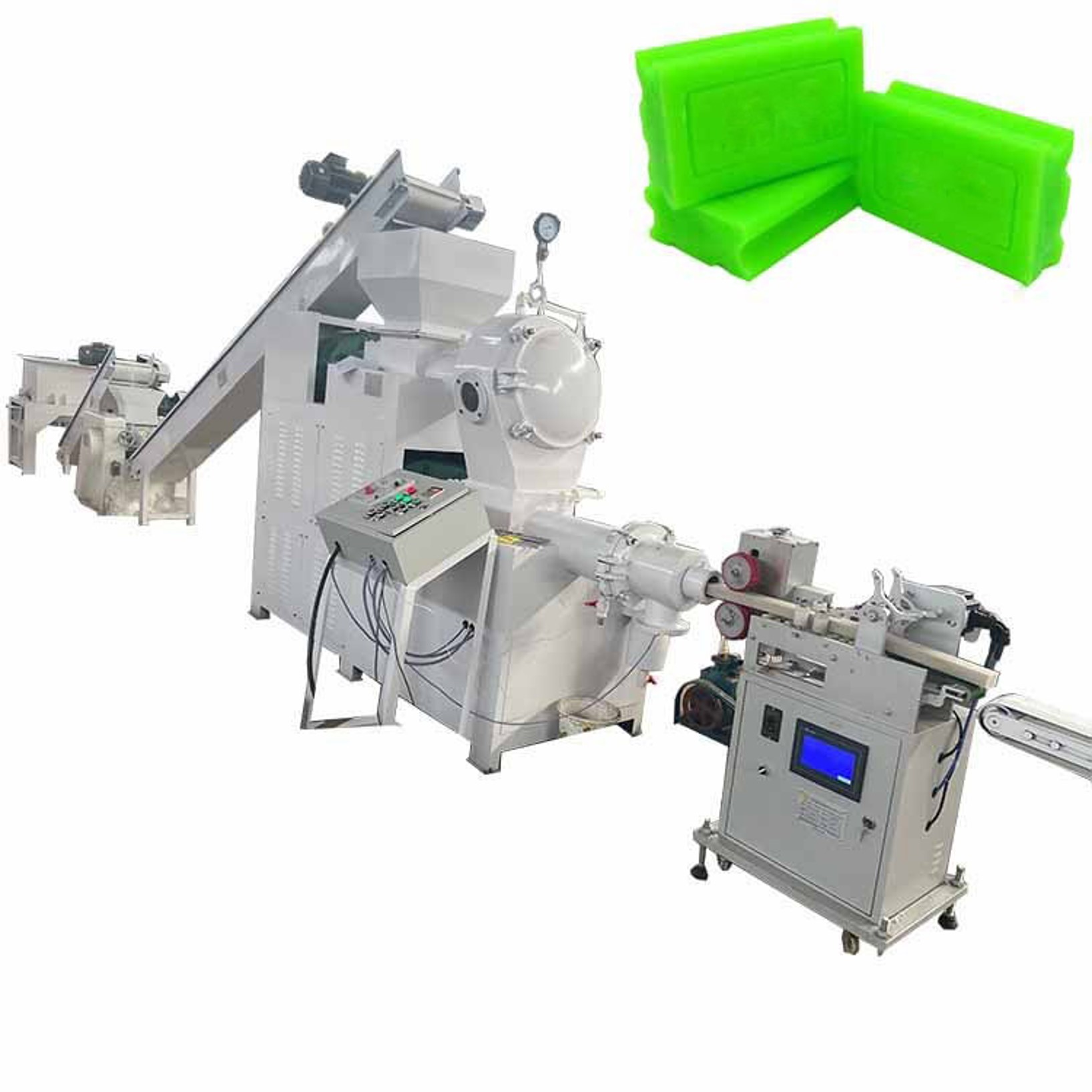

SOAP MAKING LINE

1. POWER MIXER. As the machine operates, the mixing blades break the soap chips, evenly mixing them with additives.

2. SIMPLEX REFINER The refiner kneads and homogenizes soap chips using a screw. Soap noodles pass through a drilling plate.

3. TRIPLE ROLLER The rolling mill soap chips with rollers at different speeds, achieving high quality.

4. DUPLEX PLODDER The plodder kneads and homogenizes soap chips using a screw, forming soap bars through an eye plate. A vacuum chamber removes air, improving soap quality.

5. SOAP CUTTER The automatic pneumatic cutter allows length setting via touch screen, with 0.1mm accuracy using PLC calculations.

6. AUTO-STAMPER The multi-vertical soap stamper allows easy die set changes, with fast and stable stamping. Driven by a servo motor and cam system, it operates quietly and stably.