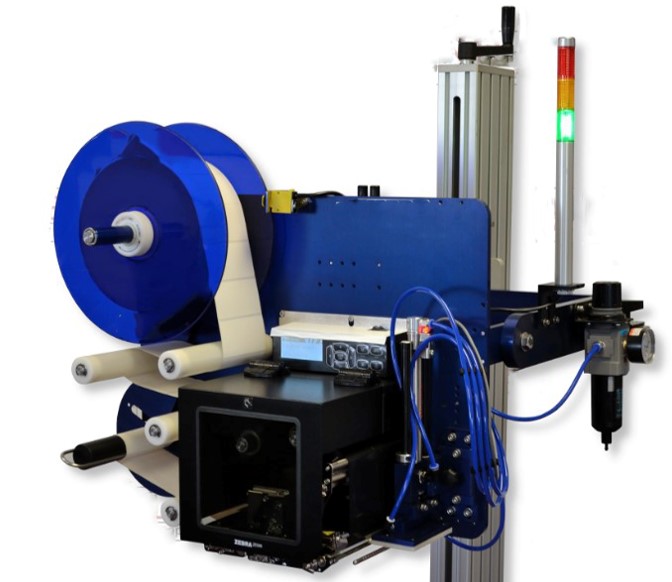

LABEL APPLICATOR

Our print and apply label applicator makes capabilities standard that were once custom on label applicators. Additional I/O points allow for easy integration to scales, bar-code scanners, product diverters, automatic machines, conveyor lines, remote triggers, tamp synchronization, and indicator signals such as low label, broken web, batch done, and more. Selections of several standard features are easy to enter using the hand-held touch screen interface. The controller software is user friendly and password protected. Selectable features include batch counter, job storage, operational modes, trigger polarity, and printer status outputs. With more built-in features and capabilities than any other printer applicator on the market.

SPECIFICATIONS

| Print Speed | Up to 16 inches/second and, depending on label size, approximately 10-90 labels/minute |

| Interface Sensors | Product Sensor - Photoeye / Limit Switch / Plc Input Auxiliary Output With Connector |

| Label placement tolerance | Up to +/- 1/32" when labels are produced to specifications & product handling is controlled |

| Electrical input | 110vac / 60hz -- 5 amps |

| Label roll capacity | 12" max outside diameter, wound on a 3" core. Die-cut waste removed with a minimum 1/8" separation between labels in running direction |

| Air requirements | 80 psi / 3 cfm required |

| Acceptable label sizes | Minimum 1.0" wide x 1/2" long maximum 6.0" wide x 14" long (optional sizes available |

| Application methods | Tamp, smart-tamp, flag, blow, adjacent panel, corner-wrap, swing tamp, pallet label & custom application modules |

| Environment | Operating 50-95 degrees f (10-35 degrees c) 15-85% relative humidity, non-condensing |

| General size | 28" wide x 26" deep x 26" high |